Test Solution Business Unit develops wafer testers in-house which are utilized during the semiconductor manufacturing process to test the performance of the products and to separate good products from defective products. Such testers are mainly adopted as test solutions for mass production lines of NAND flash memory products and their applications are expanding to test CMOS image sensors and MEMS products as well.

As INNOTECH configures the optimal test circuits based on various customers test requirements, INNOTECH products enhance test efficiencies and test qualities, reduce power consumption, CO2 emission, footprint for installation, equipment costs and so on and substantially contribute to customers’ reduction of test costs.

INNOTECH (Hardware design, software development, product support)

→ Electronics manufacturing services (outsourcing manufacturing of wafer tester)

→ Final products (NAND flash memory tester, CMOS image sensor tester, MEMS handler)

INNOTECH has many years of expertise in the tester market for NAND flash memory products and has kept working on reduction of footprint, power consumption and enhancement of test efficiency of its testers. Then, it has gradually shifted its focus to mass production testers and it has ultimately succeeded in developing the ultra-small size model, which can be integrated to a prober system with a capacity to support maximum 12 test equipment. The model is currently provided to its customers.

By integrating multiple test equipment, tests may be run in a more efficient manner and the system becomes more compact, low-power, thus the clean rooms at mass production facilities are maintained more efficiently.

As a result, customers can dramatically reduce their costs and the environmental impact as well.

Test process is in the downstream of the entire semiconductor manufacturing flow. The test results must be reported back promptly to the upstream so that necessary improvements are made rapidly, such as adjusting the process control equipment.

The cutting-edge bitmap test system developed by INNOTECH collects data high-speed, analyzes the massive collected data by edge processing on the tester side, and sends such analysis results to the host computer on the manufacturing facility side over high-speed network; thus, effective improvement measures are rapidly implemented at each manufacturing process.

As a result, the yields are dramatically enhanced and the amount of waste is reduced as well.

CMOS Image Sensor Test System consists of image-processing hardware and its software library. INNOTECH product utilizes the high-speed image processing software library developed by Regulus Co., Ltd which is one of the INNOTECH group companies and achieves dramatic reduction of test time.

This technology may be applied to a wide range of applications, such as to test camera modules and to test lenses themselves.

INNOTECH actively pursues such horizontal expansion of its technology and one of the application areas is a tester which supports the on-chip color filter test process. This test equipment contributes to digitization of OCF manufacturing process.

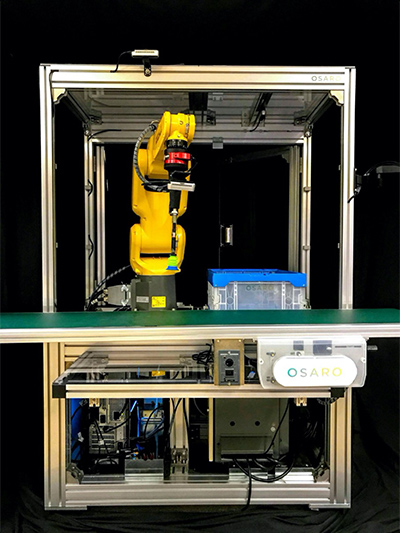

INNOTECH has opened the “AI Picking Lab” jointly with OSARO, Inc. in order to expand the robotics automation service business in Japan and strengthen its customer service scheme.

INNOTECH makes picking automation by AI software more general-purpose by integrating robots and peripherals together and presents it.

Especially AI Vision of OSARO performs well for food, cosmetics and medicine industries and targeting to such markets, INNOTECH actively promotes its solution for logistics and factory automation so that it will contribute to resolve one of the major social issues, which is labor shortage.

INNOTECH adopts the so-called fabless model as it designs and develops hardware products in-house and has them manufactured at leading Japanese electronics manufacturing service (EMS) companies.

INNOTECH fully plans and designs the product and utilizes high-precision simulators so that the quality is already ensured during the design phase.

And at the manufacturing stage, it leverages large-scale EMS companies’ strengths, such as their procurement power of semiconductors and various components and high-quality manufacturing expertise so that the products which best fit the customers’ needs are manufactured and provided in a timely manner.